- All Products

- Shop by Brands

- BW Technologies

- BW Technologies

- BW Technologies Monitors

- Models

- BW Clip

- BW Clip4

- GasAlertClip Extreme

- GasAlert Extreme

- GasAlertMicroClip XT

- GasAlertMicroClip XL

- GasAlertMicroClip X3

- GasAlertQuattro

- GasAlertMax XT II

- GasAlertMicro 5 Series

- SamplerPak

- IntelliDox Docking System

- MicroDock II

- BW Ultra

- BW Solo

- Gas Monitors

- Gas Monitor Manufacturers

- BW Technologies

- Bacharach

- Biosystems

- Crowcon

- Draeger

- Gas Clip Technologies

- GfG Instruments

- GMI/Detcon

- Honeywell Analytics

- Industrial Scientific

- IGD

- mPower

- MSA

- RAE Instruments

- RKI Instruments

- WatchGas

- Calibration Gas

- Combustion Analyzers

- Water Quality

- Reliability Instruments

- Refractometers

- HVAC

- Weather

- Temperature

- Laboratory

- Sound

- IAQ

- Electrical

- All Categories

Computed Gas Exposures

Computed Gas Exposures

Warning

WarningTo prevent possible personal injury, do not deactivate the detector during a work shift. TWA, STEL, and MAX readings reset when the detector is deactivated.

| Gas Exposure | Description |

TWA (H2S and CO only) | Time-weighted average (TWA) based on accumulated exposure to toxic gases averaged over a workday according to OSHA method. Default: OSHA 8 hour moving average. User-defined: 4-16 hour moving average. |

STEL (H2S and CO only) | Short-term exposure limit (STEL) to gas based on a 5-15 minute user-defined period. |

Maximum* (peak) | Maximum (MAX) concentration encountered during work shift. |

* For oxygen, it is the highest or the lowest concentration encountered.

Viewing and Clearing Gas Exposures

To view the TWA, STEL, and maximum (MAX) readings, press  twice

rapidly. The LCD first displays the current time and date.

twice

rapidly. The LCD first displays the current time and date.

Then, the TWA gas exposures display.

Next, the STEL gas exposures display

Next, the MAX readings display

Last, the CLEAR ALL readings screen displays.

To clear the TWA, STEL, and MAX exposure readings, press  when

the following screen displays.

when

the following screen displays.

Warning

WarningFollow all safety procedures as defined by your employer.

Deactivating the detector clears all readings. Confirm with your supervisor before clearing TWA and STEL alarms.

Gas Alarm Setpoints

The alarm setpoints trigger the gas alarms and are described Table 9

Table 9. Gas Alarm Setpoints

| Alarm | Condition |

| Low alarm | Toxics and combustibles: Ambient gas level above low alarm setpoint. Oxygen: Ambient gas level may be set above or below 20.9% (or 20.8%). |

| High alarm | Toxics and combustibles: Ambient gas level above high alarm setpoint. Oxygen: Ambient gas level may be set above or below 20.9% (or 20.8%). |

| TWA alarm | Toxic only: Accumulated value above the TWA alarm setpoint. |

| STEL alarm | Toxic only: Accumulated value above the STEL alarm setpoint. |

| Multi-gas alarm | Two or more gas alarm conditions simultaneously. |

Resetting Gas Alarm Setpoints

Table 10. lists alarm setpoints as defined by Occupational Safety and Health Association (OSHA).

Note

Standard factory alarm setpoints vary by region.

Table 10. Sample Factory Alarm Setpoints

| Gas | TWA | STEL | Low | High |

| O2 | N/A | N/A | 19.5% vol. | 23.5% vol. |

| LEL | N/A | N/A | 10% LEL | 20% LEL |

| CO | 35 ppm | 50 ppm | 35 ppm | 200 ppm |

| H2S | 10 ppm | 15 ppm | 10 ppm | 15 ppm |

Note

To disable an alarm, set the alarm setpoint to 0 (zero) in Fleet Manager II.

To change the factory-defined alarm setpoints, refer to the following in User Options:

Stopping a Gas Alarm

The low and high alarms stop when the ambient gas concentrations returns to a concentration below the low alarm setpoint.

Note

If alarms are set to latch, press  to reset the alarms

to reset the alarms

The detector computes the TWA value based on OSHA standards and the STEL value based on a user-defined 5 to 15 minute interval. Refer to STEL Interval.

The TWA and STEL alarms can be stopped either by

- deactivating and then reactivating the detector, or

- clearing the TWA/STEL/MAX exposure readings. Refer to Viewing and Clearing Gas Exposures.

Caution

CautionFollow all safety procedures as defined by your employer. Confirm with your supervisor before clearing TWA and STEL alarms.

Sensor Alarm

The detector tests for missing or defective sensors during the startup self-test and continuously thereafter. If a sensor fails the self-test, Err displays above the gas type of the failed sensor. If a sensor fails, refer to Troubleshooting.

Pump Alarm

The pump draws air over the sensors continually. If the pump stops operating or becomes blocked, the detector activates the pump alarm.

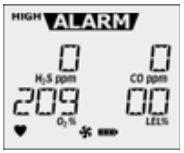

During a pump alarm, HIGH and  display, and

display, and  flashes.

flashes.

Note

The pump alarm displays the same as a high alarm, except

that  flashes. Verify that a pump alarm is occurring before

clearing the hose.

flashes. Verify that a pump alarm is occurring before

clearing the hose.

The pump alarm continues until the alarm is acknowledged by

pressing  .

.

1. Clear the blockage and press  to acknowledge. If

Force Block Test is enabled, the detector automatically

launches a pump test to verify the pump is operating correctly.

to acknowledge. If

Force Block Test is enabled, the detector automatically

launches a pump test to verify the pump is operating correctly.

2. If the pump test is successful, the detector returns to normal operation.

If the pump test is unsuccessful, refer to Troubleshooting for possible causes and solutions.

Low Battery Alarm

The detector tests the battery on activation and continuously thereafter. Battery power is continually displayed during normal operation. If the battery voltage is low, the detector activates the low battery alarm.

The low battery alarm continues 10 minutes. If the battery voltage drops too low, the detector activates the automatic deactivation alarm.

Automatic Deactivation Alarm

If the battery is depleted below the minimum operating voltage, a sequence of ten sirens and alternating flashes activates with 1 second of silence in between. The sequence repeats seven times. The following screens displays and the detector deactivates.

To charge the detector, refer to Charging the Battery